News -

Yamaha's Marine Business-Growing as a System Supplier -Yamaha Motor Monthly Newsletter(Sep.15, 2017 No.57)-

In 1960, Yamaha Motor followed on its success with motorcycles by entering the marine industry, and began manufacturing and selling FRP (fiber-reinforced plastic) motorboats and outboard motors. By developing a diverse line of products backed by tireless marketing efforts, Yamaha rose to become Japan’s leading comprehensive manufacturer of marine products.

On the global market as well, the outstanding reliability and wide range of Yamaha outboard models led to rapid business growth. The steady upward progression for the company’s second core line of business led to Marine Business Operations accounting for about 20% of overall sales in fiscal 2015 with annual net sales of approx. 300 billion yen.

In this issue, we introduce the ongoing challenge of Yamaha’s marine business to achieve further growth competing in the three trillion yen global marine market as laid out in the company’s current medium-term management plan (2016–2018).

Big-Horsepower Class Outboards: Key Players in Yamaha’s Growth Strategy

The core products of Yamaha’s marine business today are its outboard motors, accounting for 56% of its roughly 300 billion yen in annual net sales. Global outboard motor demand in 2016 was approx. 717,000 units, and Yamaha outboards comprised some 41% of that total with around 292,000 units shipped. In North America, the world’s largest outboard market, models of 100 horsepower and up are driving the robust recovery in demand following the 2008 global recession, and this momentum has also spread to Oceania and Europe, buttressing the market worldwide.

“If you categorize under-25 hp outboards as ‘small class,’ 30 to 90 hp models as ‘mid-class’ and 100 hp and over models as ‘large class,’ compared to 2010 when the three classes each accounted for about one-third of our sales, the large class now comprises about half of our overall sales,” says the Senior General Manager of Yamaha’s Marine Business Section. “Boats are typically propelled by stern-drive, inboard or outboard engines, and we believe builders and owners shifting away from using inboards for large boats to using outboards instead as the power unit of choice has played a large part in shaping our current sales breakdown.”

| In markets like North America in particular, boats designed to mount multiple high-horsepower outboards are popular. |

Many inboard engines are diesels, which deliver a lot of torque but don’t provide as much speed and have to be housed within the boat, making the boat interior more cramped. The smell and vibration they generate can also bother users, and breakdowns require more time and effort to repair. With outboards on the other hand, they are mounted outside on the boat’s hull, bringing advantages like improved space efficiency, easier maintenance and faster motor replacement. But, as increasingly strict emissions regulations were implemented in markets like North America and Europe from the 1980s, it was some time before outboard manufacturers released high-output models suited for larger boats.

Yamaha was quick, however, to begin building a full lineup of 4-stroke models as an alternative to 2-strokes. And from around the year 2000, the company began focusing its efforts on developing large, high-output 4-stroke offerings. Releasing model after model in its series of 4-stroke V8s (350 and 300 hp) and V6s (300, 250, 225 hp), all were well received by the market.

With this product strategy bearing fruit, Yamaha not only helped trigger the shift to outboards for larger boats but also stimulated the outboard industry as a whole.

Becoming a System Supplier: Integrating IT and Boat Operation

This shift in propulsion from inboards to outboards has changed the forms and design of large boats and even the lifestyles of their users in recent years. Traditional offshore cruisers with cabins for overnight stays on the water were quickly eclipsed by boats designed for speed mounting three or four 300 or 350 hp outboards—the leading trend today.

With this unbeatable power, boaters can quickly get to their chosen waters to enjoy sport fishing or cruising, and then return to shore that same day to spend the night in a nearby hotel or vacation home. As this boating style became more common, it led to changes in the designs of boat hulls as well as onboard equipment to better suit the new types of usage.

However, as boats become larger and begin requiring two or three outboards, operation and piloting also required greater levels of skill. This is especially apparent when leaving port or docking, which involves small but complex maneuvers difficult to master even for experienced boaters. “We wanted to do something to solve this problem, so we worked together with Volvo Penta to develop a solution, and that’s the Helm Master (released in 2013),” says the Senior General Manager.

| With a single joystick, the Helm Master system performs all of the complex tasks for operating multiple outboards that once required extensive training and experience. |

“The benefit of this control unit is that it electronically coordinates all of the shifting, throttle work, steering, etc., for multi-outboard rigs and allows the user to intuitively steer the boat with a single joystick, whether it’s moving directly side to side or rotating the boat in place.

Thanks to this system, we were able to win solid demand for boats using several high-power outboards. We then decided to further develop and expand upon this approach and develop highly reliable ‘package boats’ similar to cars where these systems help make boating easier for users. That’s the basis for our system supplier strategy.”

Boats are products that tend to have distinct design features inherent to their locality. Boatbuilders have applied their know-how to designing hulls that fit the culture, environment and uses of the region, outfitting boats in accordance with local needs. Even as boats have become larger and an array of new navigational equipment and boat control devices have come into use, this trend has not changed.

“But, if you outfit a boat with engines using their own control systems and then peripheral equipment from different manufacturers without any alterations, the boat ends up cluttered with all kinds of different switches and gauges,” continues the Senior General Manager. “That only makes the craft difficult to operate. What Yamaha is aiming to create is one integrated system for management and display by taking all the information from the radar, GPS, sonar, cameras, etc., and bringing it together. That’s to say, we coordinate the engine, steering and various support systems to create a fully integrated boat control system that enables operation with one remote control lever and one steering wheel or joystick. We then refine it into a comprehensive package that we can offer to as many boatbuilders as possible with Yamaha’s signature precision, quality and reliability.”

Technical Development: Taking Steps to Improve Everything One by One

The number of devices and equipment typically grows the bigger the boat is, so one system integrating them all for a boat cockpit that is less cluttered, easier to use as well as more fun to use would be welcomed by any boater. It was from that idea that Yamaha came up with its approach and has continued working with that customer-oriented mentality.

Although work to become a full-fledged system supplier is currently in progress, Yamaha’s high-horsepower outboards— the foundation of the strategy—have already won a solid reputation in the market and the pace of product development and sales is healthy. The Helm Master system that now forms the core of Yamaha’s boat operation package has also gained dynamic positioning capability via GPS, making it even more convenient.

Furthermore, the new CL7 multifunction touchscreen display released in Spring 2017 shows a wide range of information, from Helm Master and outboard engine info to GPS, radar and other peripheral equipment data, and represents another surefooted step in Yamaha’s strategy.

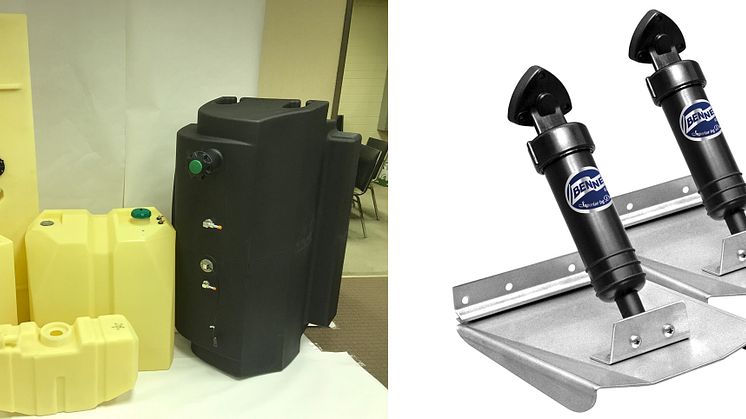

“What’s more, in the summer of 2017 we acquired two peripheral equipment manufacturers, one specializing in plastic fuel tanks and the other in the trim tabs attached to a boat’s hull to control its attitude in motion,” says the Manager.

| The CL7 color touchscreen simplifies and consolidates numerous instrument gauges into one display. |

“Trim tabs help the boat reach its most stable planing position as quickly as possible, and thus contribute to improved comfort and fuel economy. Our target is to create a boat control system that links the engines and trim tab to achieve an even higher level of functionality. In-depth development is yet to begin, but Yamaha now possesses most of the essential technical elements needed for it. We want to create systems that are flexible as well as easy to implement for boatbuilders worldwide so that we can bring the joys of the marine lifestyle to more people,” the Manager concludes.

The day may not be far off when we see large boats powered by multiple outboards being piloted on the waters of the world with the ease and relaxed feel of a scooter.