Press release -

HANNOVER MESSE 2019 Yamaha Motor Exhibits at World's Leading Industrial Technology Trade Fair - Abundant Robot Line-up Provides Optimal Solutions for Diverse Automation -

IWATA, March 4, 2019 - Yamaha Motor Co., Ltd. (Tokyo:7272) announced today that it will exhibit a booth based on the theme of “YAMAHA ROBOT BEST SOLUTION - Improved Production Line Performance,” at the HANNOVER MESSE 2019, a B to B industrial technology trade show to be held in Hannover, Germany, from Monday, April 1 to Friday, April 5, 2019.

The HANNOVER MESSE is the world's leading industrial trade fair, at which leading-edge industrial technology and products are gathered in one place. (The 2018 event saw exhibits held by approx. 6,500 companies attracting around 220,000 visitors).

The booth has increased space to about twice that of last year where it will showcase demonstrations such as the “Linear Conveyor Module LCM 100,” a linear motor-based transport robot, and a SCARA robot which boasts high speed and high accuracy. These exhibits work toward greater productivity and improved variability on production lines, providing best solutions for factory automation.

■Overview of HANNOVER MESSE 2019

| Event Period: | April 1 to 5, 2019 |

| Venue: | Hannover Exhibition Grounds, Germany |

| No. of exhibitors/ | |

| No. of Attendees: |

Approx.6,500 Companies /

Approx. 220,000 Attendees (2018 Results) |

| Website: | http://www.hannovermesse.de/home |

■ Overview of Yamaha Motor Exhibit

| Exhibit Space: | Hall 17, B68 |

| Exhibit Contents: |

Exhibition and demonstrations

- Linear Conveyor Module LCM100 - Robot Vision “iVY 2” & Multi-Axis Controller “RCX 340” - SCARA robot “YK 400 XR” & Cartesian Robots |

Website:

<English>

https://global.yamaha-motor.com/business/robot/event/2019hannover_messe/

<German>

https://global.yamaha-motor.com/business/robot/sp/

■Yamaha Motor: Exhibitions and Demonstrations

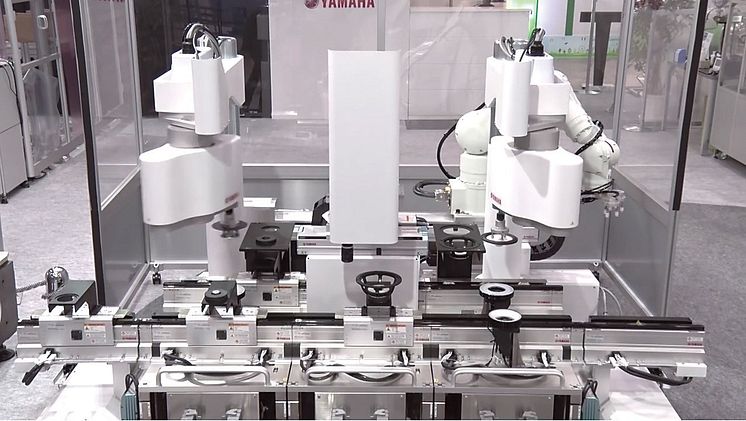

1) Speaker assembly demonstration using the LCM 100 transport robot

|

Linear Conveyor Module LCM100

|

|

2) On-the-fly Function Demonstration (non-stop recognition camera)

Robot Integrated Vision System “iVY 2” & Multi-Axis Controller “RCX 340”

|

Our exhibition will introduce a function that can shorten pick and place tact times with position correction after test piece handling. With the robot-integrated vision system "iVY2," through the multi-axis controller “RCX 340” capable of synchronous operation with multiple stand robots, recognition, correction and mounting can be performed without stopping robot operation, working to help improving throughput significantly. |

|

3) Auto parts sealing demonstration

|

SCARA robot “YK 400 XR” & Cartesian Robots

|

|

■European Industrial Robot Market Overview

(Total welding, painting/coating, actuator, assembly, conveyance, and clean conveyance system)

The industrial robot market in Europe continues to grow due to the declining labor force, rising wages, increased factory automation and quality improvement needs.

■ History of Yamaha Motor Industrial Robots

| 1974: | Yamaha Motor begins research and development into industrial robots in order to streamline production and increase machining precision in its own motorcycle factories |

| 1976: | SCARA robots introduced to Yamaha Motor motorcycle production lines |

| 1984: | IM Business Unit established (Yamaha Motor Hamakita Plant) / SCARA robot sales begin |

| 1991: | IM Technology Center completion (Sodecho, Hamamatsu city, Shizuoka Prefecture) |

| 2006: | IM Technology Center and factory expansion |

| 2013: |

China (Suzhou City) sales office established

Linear Conveyor Module LCM100 is launched |

| 2016: |

Integrated control robot system “Advanced Robotics Automation Platform” is launched

Launch of Linear Conveyor Module “LCM-X”, and Single-axis robot “GX Series” Launch of Stepping Motor “YLE Series,” and Integrated Controller “THX Series” |

| 2017: | New Robotics Business building begins operation |

| 2018: |

First exhibition at HANNOVER MESSE 2018

Opening of the Yamaha Motor Advanced Technology Center (Yokohama) |

Yamaha Motor’s lineup of products to powerfully support the automation of production sites is wide-ranging in variation. YMC builds on these strengths to pursue greater efficiency and quality in increasingly complex, diverse, and high-speed production sites.

Topics

Categories

*This is a dedicated e-mail providing Yamaha Motor PR materials for viewing by media journalists.

We request that you refrain from using the materials and photographs on this e-mail for purposes other than media reporting.