Press release -

Yamaha Motor Releases High-Function 2-axis Robot Controller - RCX320 - Equipped with real-time output function for predictive maintenance info -

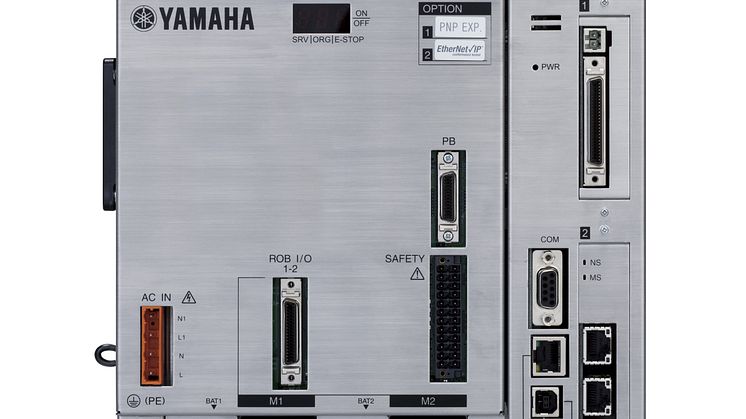

IWATA, November 1, 2019 - Yamaha Motor Co., Ltd. (Tokyo: 7272) announced today that its new RCX320 will go on sale from December 1. The RCX320 is a 2-axis model of the RCX340 multi-axis robot controller, which has become a best seller due to its high performance and ease of use.

The

RCX320 inherits the advanced functionality and flexible expandability of the RCX340 realizing synchronous control of multiple robots, and a high-level equipment construction. Compared to previous models RCX221/222, basic performance has improved significantly, such as the multi-tasking option number, memory capacity, and number of points. In addition, link functionality using YC-Link/E, Ethernet/IP, EtherCAT, and PROFINET are supported, along with the newly installed real-time output of predictive maintenance information ability.

This contributes to the realization of an “unstoppable production line” by enabling flexible equipment construction, faster execution speed of various applications, more comfortable operability, and higher precision for trajectory accuracy.

This product will be on display at the " International Robot Exhibition 2019" being held at Tokyo Big Sight from December 18 (Wednesday) to 21 (Saturday).

Main Features of the RCX320

Significantly Improved Basic Performance

Base performance is greatly improved on previous models

RCX221/222.

- Multi-tasking: Up to 16 tasks (

RCX221/222: 8 tasks maximum)

- Memory capacity: 2.1MB (

RCX221/222: 364KB)

- Number of programs: Up to 100 programs (Equivalent to the

RCX221/222)

- Points: 30,000 points (

RCX221/222: 10,000 points)

Controlling ability from small to large cartesian robots via one unit

All Yamaha Motor 2-axis robots from small to large can be used with this machine, including the XYX series 2-axis cartesian robot, the FLIP-X series servo motor single-axis robot, and the PHASER series linear motor single-axis robot etc.

Easy control of dual robots

You can easily control a dual robot that drives two axis synchronously.

Achieves 6-axis* control at low cost

In addition to the control of 2-axis robots, inter-controller communication YC-Link/E can be used to easily connect to the RCX340. Low cost 6-axis* control capability is also available.

*Not applicable in the articulated robot YA series.

Synchronous control of multiple robots

Inter-controller communication YC-Link/E enables synchronous control of multiple robots such as in cartesian robots + SCARA robot combinations. Significant reductions in system startup times are achievable as operations can be carried out by a program using only the master controller. The RCX320 controller is compatible with both master and slave specifications, enabling a flexible system build.

*Up to four RCX320 and RCX340 units can be connected by the inter-controller communicating YC-Link/E.

Enhanced field network support and other optional functions

Supports six types of international field networks: Ethernet/IP, EtherCAT, CC-Link, DeviceNet, PROFINET, and PROFIBUS. Building a system that meets your needs is more possible now that the RS-232C and Ethernet ports are equipped as standard, and optional functions such as gripper and vision systems are also supported.

About 3 times the CPU processing capacity

The processing capacity of the CPU has been tripled compared to the previous model. Control performance, such as motion trajectory and internal processing time, is greatly improved.

Improved trajectory accuracy

As the unit is equipped with a servo motion engine equivalent to RCX340, the follow-up performance has been improved compared to the previous model along with smoother movement. Shortened positioning time and improved trajectory accuracy.

Supporting software RCX-StudioPro

Compatible with RCX-StudioPro common to RCX340. As RCX320 is equipped with an emulator function, programs can be created and debugged without a controller. The cycle time between two points can be calculated quickly, and the optimal robot can be easily selected. Even after startup, real-time tracing and debugging information of multiple tasks can be displayed at the same time to check the status.

Industrial Ethernet option real-time output functionality

An “unstoppable production line” is achieved when an industrial Ethernet option (Ethernet/IP, EtherCAT, or Profinet) is selected, this enables information necessary for predictive maintenance such as error status, current positions, electric current values, motor load rates, and operation times to be output in real time.

RCX320 Basic Specifications

Topics

Categories

*This is a dedicated e-mail providing Yamaha Motor PR materials for viewing by media journalists.

We request that you refrain from using the materials and photographs on this e-mail for purposes other than media reporting.